Safety factor, independence from weather conditions.

Competing with natural conditions is always a useless exercise for technical systems.

If we take trout farms located in mountainous regions with natural clean water, in most cases they have free water resources and not a RAS can compete with such a farm in terms of cost.

However, the picture changes significantly when factors appear that destabilize the normal operation of flow-through facilities. For example, in mountainous areas with clay or black soil, the turbidity of the water increases significantly during the rainy season. The fish stops eating normally (does not see food), the gills become clogged, immunity decreases, and the level of diseases increases. In such cases, there is a need to use additional technological solutions.

Using the example of one of the trout farms, a technical and economic analysis was made to choose the path for its modernization.

To begin with, a mathematical model of the dependence of water consumption on planting density was built.

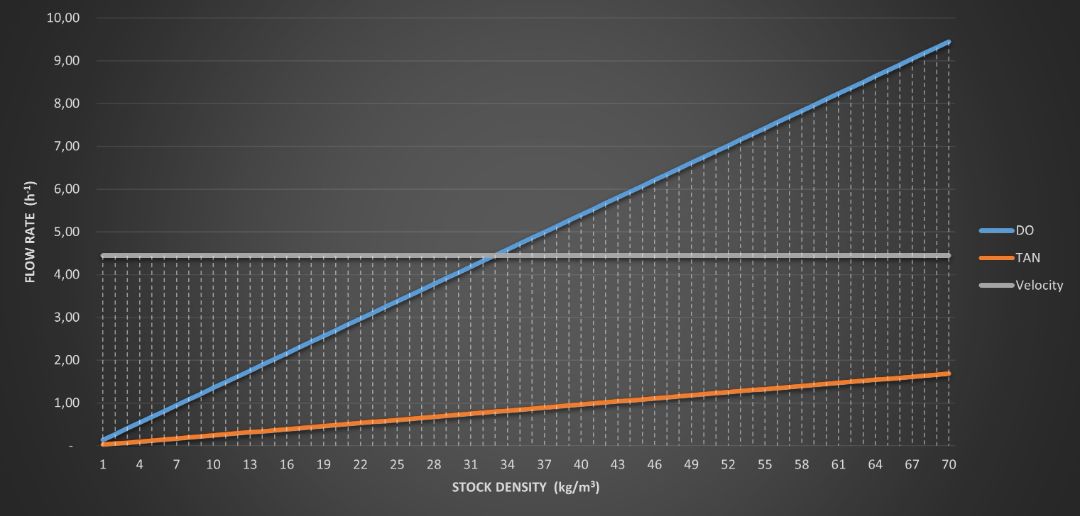

Water exchange was determined according to 3 criteria:

From the graph it became clear that the dissolved oxygen level and flow velocity have the greatest influence. At the intersection of these trend lines is the optimal planting density.

Based on the model, the 3 most optimal modernization paths were identified:

1. Flow-through system with a stocking density of 30 kg/m3 – at the intersection of oxygen requirements and flow speed. Water supply in normal mode is 4 time per hour (h-1). During the period of turbid water, the water supply can be reduced by approximately 4 times until the maximum permissible concentration according to TAN is reached – 1 mg/l. Mechanical filters with a 10-micron screen are installed for this mode. At the same time, oxygen supply is additionally organized.

2. Semi-closed system. All input water passes through filters, with a constant water exchange rate of 1 time per hour. Inside the system, the water is circulated through the tanks 4 times, while being saturated with oxygen, which allows the planting density to be increased to 41 kg/m3

3. RAS. Daily water exchange is 20%. All input water is filtered through 10-micron mechanical filters and undergoes UV sterilization. There are 2 independent RAS systems inside, providing 4x water exchange in the tanks and a stocking density of 80 kg/m3.

Multiobjective optimization included, factors such as:

According to the results, the most effective technology turned out to be the closest to natural technology – option 1, filtration during the period of turbidity with oxygen supply.

Capex for 1 ton of products produced per year are $2.47 /t

0 additional kWh (0.3 kWh/t with filtration)

Option 2

Capex per 1 ton of products produced per year are $2.93 /t

Specific hourly electricity consumption is 0.52 kW h/t – in normal mode, 0.73 kW h/t during filtration

Option 3

Capex per 1 ton of products produced per year are $3.74 /t

Specific hourly electricity consumption is 0.93 kWh/t

At the same time, non-numeric criteria (security level, uniformity of capacity) in this case also indicated the effectiveness of Option 1.

Thanks for reading the article!

If you have any questions, write in a way convenient for you: CONTACTS

© Dmitry Yakovlev